Recipe & Batch Control

Our Recipe and Batch system streamlines recipe creation and management, ensuring consistent, high-quality production. With precise control over ingredient proportions and tolerance settings, it integrates seamlessly with your weighing platforms to automate and simplify the formulation process.

Learn More >

Batch processes can be seamlessly monitored from start to finish, ensuring complete visibility and consistency throughout production

Recipe Formulation

Develop and manage recipes with ease using our intuitive interface. The system allows you to set and control ingredient proportions, tolerances, and mixing instructions systematically.

-

Ingredient Proportion Control:

Adjust ingredient quantities with precision to maintain consistent batch quality, ensuring that each production run meets your exact standards. Our system allows for detailed control over ingredient measurements, helping to prevent variability and maintain product uniformity.

-

Tolerance Settings

Define acceptable variations to ensure consistency across all batches. By setting specific tolerance levels for ingredients and processes, you can reduce discrepancies and maintain quality control throughout your production. This feature helps to ensure that every batch adheres to your established standards, minimizing waste and maximizing efficiency.

-

Automated Replenishment

Set automated reorder points and receive alerts when stock levels fall below your predefined thresholds. Our system can even generate purchase orders automatically, ensuring your inventory is always at optimal levels without manual intervention.

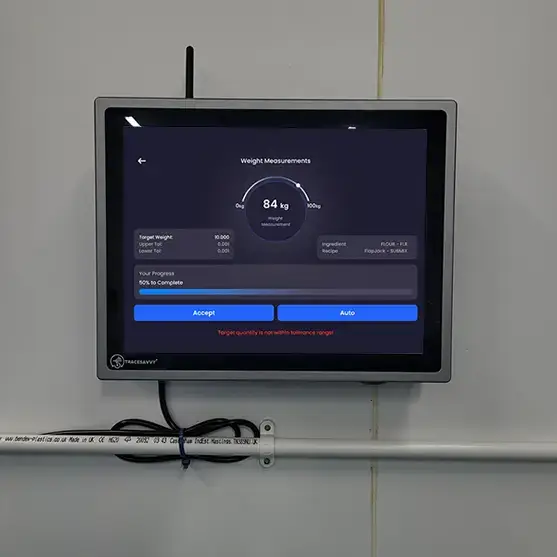

Batch Control

Easily manage batch weighing with our production floor application, designed for seamless integration with your existing weighing platforms via RS232 or wireless connections. The intuitive interface allows precise control over ingredient proportions, tolerances, and mixing instructions. Our system ensures that each batch is weighed accurately, maintaining consistency and quality across your production process.

-

Real-Time Stock Display

Monitor stock levels in real-time to see exactly how much of each ingredient is available, ensuring you maintain accurate stock management and prevent overages or shortages as you progress through the batch.

-

Tolerance Management

Define acceptable tolerance levels for each ingredient, and receive automatic alerts if any fall outside the set range, allowing for quick adjustments to maintain consistency and quality across all batches.

-

Maintain consistent quality

Set automated reorder points and receive alerts when stock levels fall below your predefined thresholds.

-

Full Audit Trial

Every detail of your batch production is tracked and recorded with Tracesavvy. This includes step-by-step costs, the personnel responsible for each task, and precise documentation of all actions taken.

-

User Interface

The user interface is fully customizable, allowing you to tailor it to your specific needs. For example, the weighing dial can be adjusted to match your preferred style and functionality, ensuring ease of use and accuracy. This adaptability not only enhances user experience but also ensures that the system seamlessly integrates into your existing workflow.

What You Gain...

Consistency in Production

Achieve consistent batch quality by maintaining precise control over ingredient proportions and tolerances.

Real-Time Monitoring

Track ingredient usage, recipe progress, and batch completion in real-time to ensure efficiency and accuracy.

Improved Quality Control

Ensure every batch meets your quality standards with automatic alerts for tolerance deviations and progress tracking.

Streamlined Operations

Simplify production processes and reduce manual errors with automated batch control and recipe formulation.

Design, Print, and Scan Labels Throughout Production

Streamline your production process with our integrated label design, printing, and scanning features. Easily create and print batch and finished product labels directly from our system. These labels can be scanned at various stages throughout production to ensure full traceability and quality control.

- Create custom designs or use our built-in templates.

- Print batch and product labels after completion.

- Support for various label sizes and formats.

- Real-time label preview before printing.

- Generate QR codes for easy tracking and scanning during production.