Production Scheduling

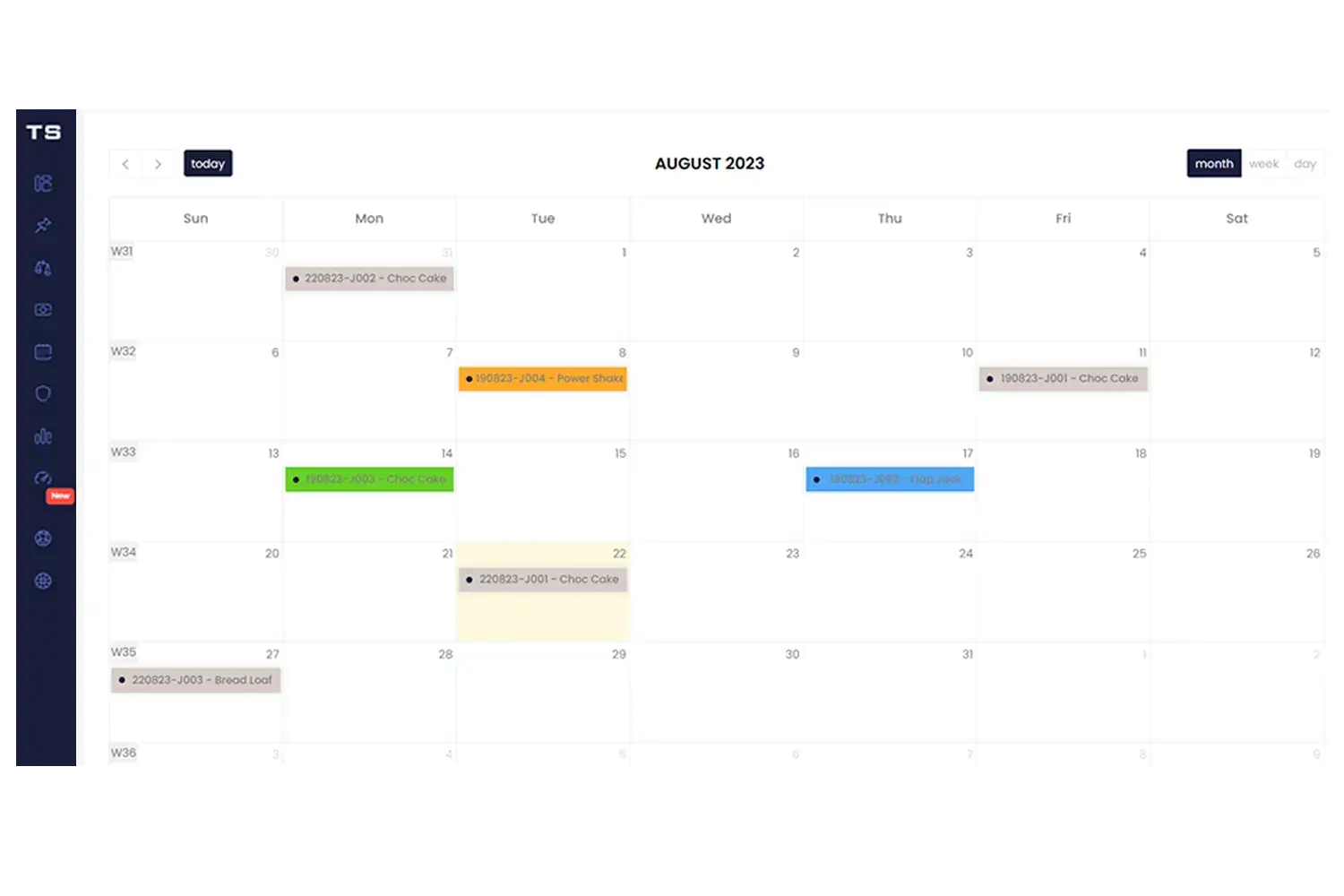

Our Production Scheduling system streamlines production by allowing you to schedule by product count, batches, or mix sizes. It automates the entire scheduling process, including calendar-based scheduling and sales order integration. The system calculates optimal batch numbers, adjusts batch sizes, and scales tolerances to ensure consistent, efficient production.

Learn More >

Requirements can be efficiently backflushed from finished products, ensuring precise material allocation, consistency, and control throughout the production cycle.

What It Offers

Easily create and manage your production schedule with our user-friendly interface. The system allows you to efficiently organize and control production timelines, batch sizes, and resource allocation, ensuring that every step of the process is systematically planned and executed for maximum efficiency and consistency.

-

Batch and Mix Size Scheduling:

Schedule production based on the number of products, specific batches, or mix sizes, giving you full control over your production process.

-

Automated and Calendar-Based Scheduling

Automate your scheduling with a built-in calendar that visually manages your production timeline. The system automatically allocates resources, schedules batches, and adjusts production plans based on your criteria, with drag-and-drop features for easy, on-the-fly adjustments.

-

Sales Order Integration

Schedule production based on sales orders, with the system automatically calculating the necessary batches and scaling batch sizes to align with demand while maintaining consistent quality and adjusted tolerances across all production runs.

Why You'll Love It...

Optimized Production Flow

Ensure seamless scheduling with automated batch planning that adapts to demand and resource availability.

Increased Efficiency

Reduce downtime and improve throughput with real-time adjustments to batch sizes and scheduling.

Enhanced Accuracy

Achieve precise production with accurate scheduling based on sales orders and inventory levels.

Better Resource Management

Optimize the use of materials and labor with scheduling that aligns production with resource availability.

Design, Print, and Scan Labels Throughout Production

Streamline your production process with our integrated label design, printing, and scanning features. Easily create and print batch and finished product labels directly from our system. These labels can be scanned at various stages throughout production to ensure full traceability and quality control.

- Create custom designs or use our built-in templates.

- Print batch and product labels after completion.

- Support for various label sizes and formats.

- Real-time label preview before printing.

- Generate QR codes for easy tracking and scanning during production.