In the world of food manufacturing, maintaining safety and quality is a non-negotiable priority. Hazard Analysis and Critical Control Points (HACCP) is a globally recognized system designed to identify, evaluate, and control food safety risks at every stage of production. By implementing HACCP, manufacturers can ensure compliance, protect consumers, and safeguard their reputation.

This blog will explore the fundamentals of HACCP, its benefits, and how adopting a robust HACCP system can transform food safety management.

HACCP (Hazard Analysis and Critical Control Points) is a systematic approach to food safety that focuses on preventing hazards rather than reacting to them. It involves identifying potential risks in the production process and establishing controls to minimize or eliminate those risks.

Key Hazards Addressed by HACCP:

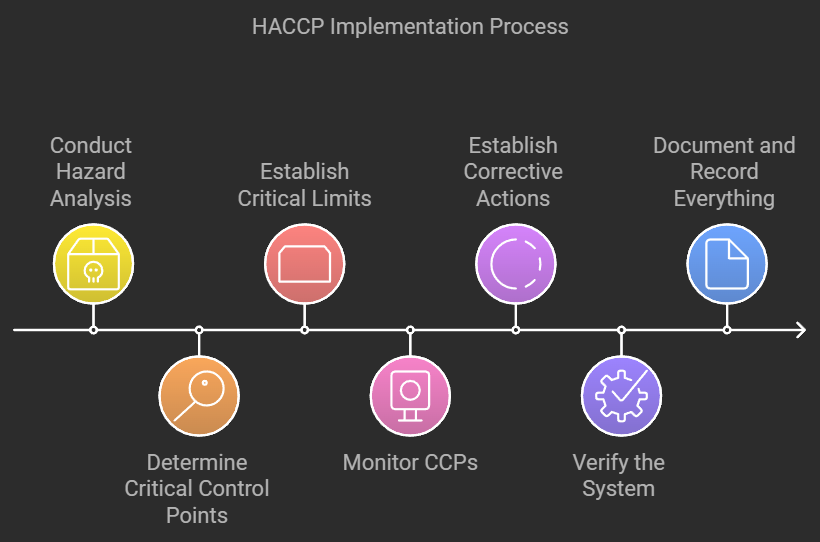

To implement HACCP effectively, manufacturers follow these seven principles:

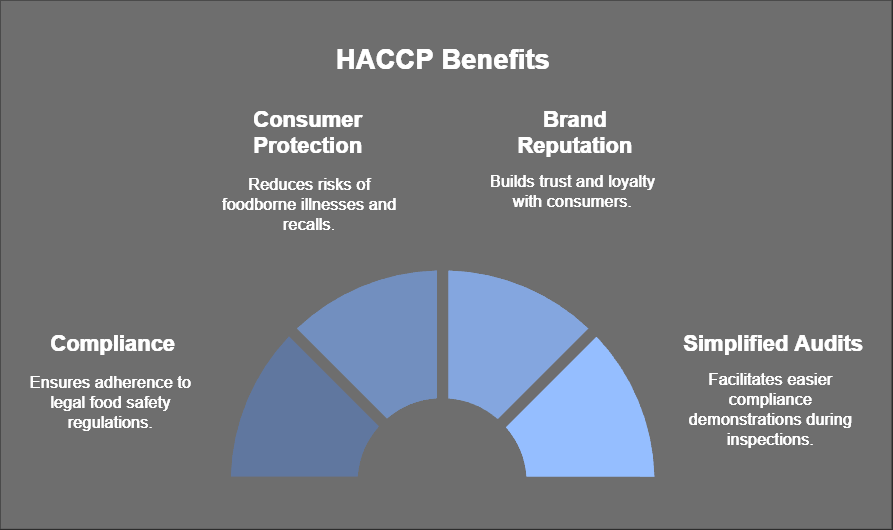

Adopting HACCP offers several advantages for food manufacturers:

a. Ensures Compliance

HACCP is a legal requirement for food businesses in the UK and many other regions, ensuring adherence to food safety regulations.

b. Protects Consumers

By proactively identifying and addressing hazards, HACCP reduces the risk of foodborne illnesses and product recalls.

c. Boosts Brand Reputation

Manufacturers that prioritize food safety build trust with consumers, fostering brand loyalty.

d. Simplifies Audits

Detailed HACCP documentation makes it easier to demonstrate compliance during inspections and audits.

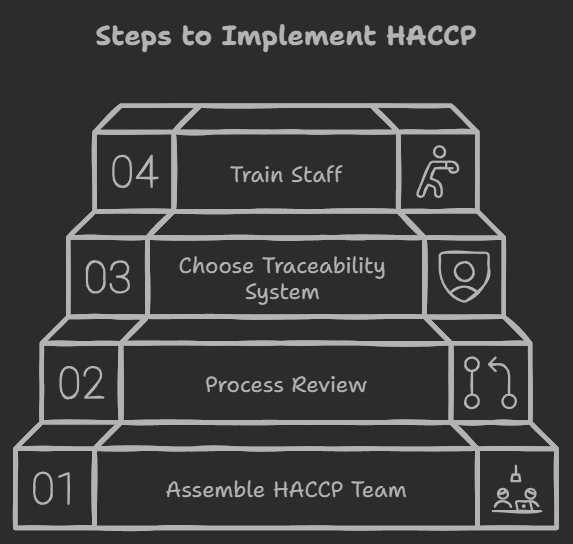

Implementing HACCP requires a structured approach and the right tools:

Step 1: Assemble a HACCP Team

Gather a team with expertise in your production processes to develop the HACCP plan.

Step 2: Conduct a Full Process Review

Map out every step in your production process to identify potential hazards.

Step 3: Choose a HACCP-Friendly Traceability System

Use software like TraceSavvy to integrate HACCP compliance into your traceability and production workflows.

Step 4: Train Your Staff

Ensure all employees understand HACCP principles and their role in maintaining food safety.

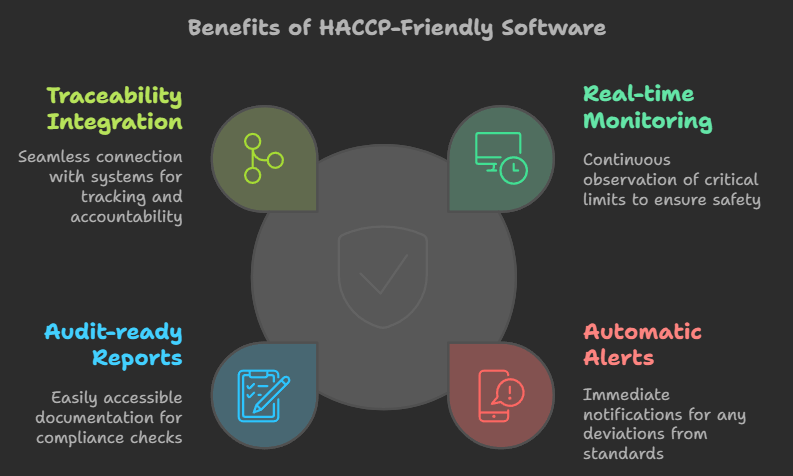

Digital solutions like traceability software streamline HACCP compliance by automating hazard analysis, monitoring CCPs, and maintaining detailed records.

Benefits of HACCP-Friendly Software:

HACCP is more than just a regulatory requirement—it’s a vital tool for ensuring food safety and building consumer trust. By adopting HACCP principles and leveraging digital tools, manufacturers can create a safer, more efficient production environment.

Ready to enhance food safety in your facility? Learn how TraceSavvy can simplify HACCP compliance and revolutionize your manufacturing processes.