Warehouse Management System

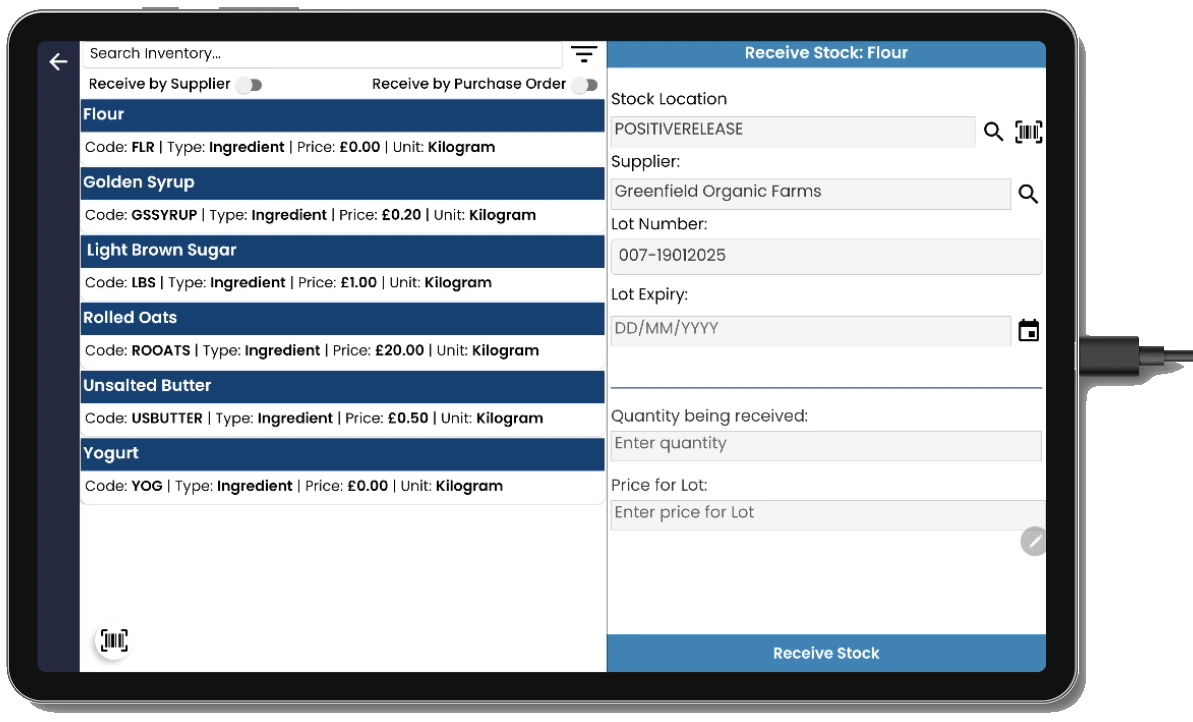

Our Warehouse Management system provides a powerful and flexible solution to help you efficiently manage and optimize your inventory processes. Whether you need to adjust stock levels, move items between locations, or manage bulk inventory actions, our system equips you with the tools to maintain accuracy and streamline operations. Additionally, stock booked into the system can be tracked seamlessly from raw materials through to the finished product, ensuring full visibility and traceability across your entire supply chain.

Learn More >

Stock can be seamlessly tracked from booking to the finished product, ensuring complete visibility across your supply chain.

Features and Capabilities

Quickly adjust inventory levels to reflect actual stock, whether correcting discrepancies or updating after a stocktake. Seamlessly move inventory between locations or warehouses, with every movement tracked for complete visibility, ensuring your data is always accurate and up to date.

-

Effortless Inventory Adjustments

Easily and accurately update inventory levels to reflect actual stock on hand. Whether correcting discrepancies or adjusting quantities post-stocktake, our system simplifies the process, ensuring your inventory data remains up-to-date and reliable.

-

Streamlined Bulk Inventory Management

Manage large-scale inventory tasks with ease using our bulk action tools. Update prices, quantities, or attributes for multiple items at once, allowing you to maintain full control over your inventory with minimal effort.

-

Automated Reorder Points

Set automated reorder points and receive instant alerts when stock levels dip below predefined thresholds. Our system can auto-generate purchase orders, ensuring your inventory stays at optimal levels without the need for manual intervention.

Save Time and Reduce Errors

By automating inventory adjustments, moves, and bulk actions, our system helps you save valuable time and minimizes the risk of human error. This leads to more accurate inventory records and smoother operations.

Cost Savings

Maintain optimal stock levels to avoid overstocking or understocking, which can lead to reduced costs and minimized waste. Accurate tracking and timely replenishment help you make the most of your resources.

User Experience

Our system is designed with the user in mind, offering an intuitive interface that makes it easy for all team members to manage inventory effectively. Customizable alerts and notifications ensure you stay informed about critical changes in your inventory.

Design and Print Labels Directly from Our System

Simplify your labeling process with our integrated label design and printing feature. Easily create custom labels using our intuitive design tools, complete with templates and a range of customization options. Print labels on demand, ensuring your inventory is accurately marked and organized with minimal effort.

- Create custom designs or use our built-in templates.

- Print labels directly from the system with one click.

- Support for various label sizes and formats.

- Real-time label preview before printing.

- Generate and include QR codes for easy tracking.